We move by Voltage

VoltaMove GmbH has set itself the goal of developing new and innovative battery storage technologies. The industrial production of battery-systems and the proposal of comprehensive energy storage solutions is the company´s mission.

VoltaMove is focusing on remote area supply and e-mobility, on land and on water, offering a broad range of hardware and software solutions. The company is providing goods & services to meet the emerging needs of the African market.

The main areas of expertise include manufacturing, assembling, importing, and exporting electronic devices such as charging stations, battery systems, controllers and electric motors.

The company is a spin-off from Fraunhofer HHI and from a private research and development company specialising in digital imbalance measurement systems for rotor vibration troubleshooting in wind turbines.

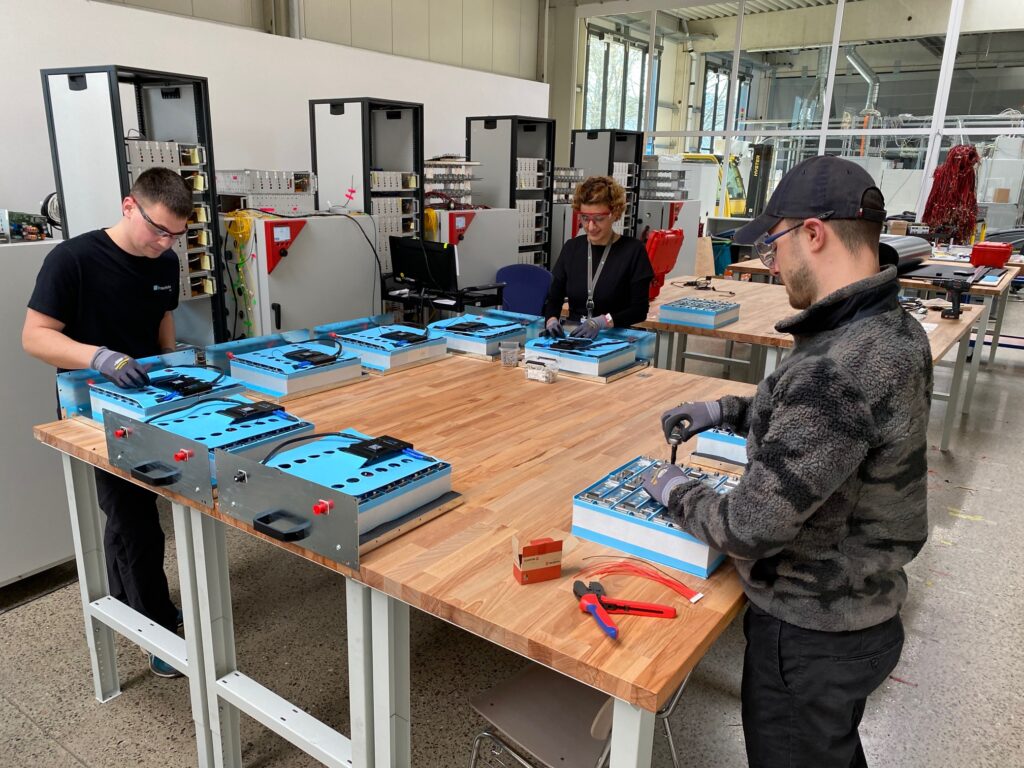

PowerPack Production

The goal of the company is the development of hardware and software as well as the industrial production of battery modules. Headquarter for the assembly of the battery systems in Goslar, Lower Saxony, Germany, because of the proximity to the Fraunhofer HHI.

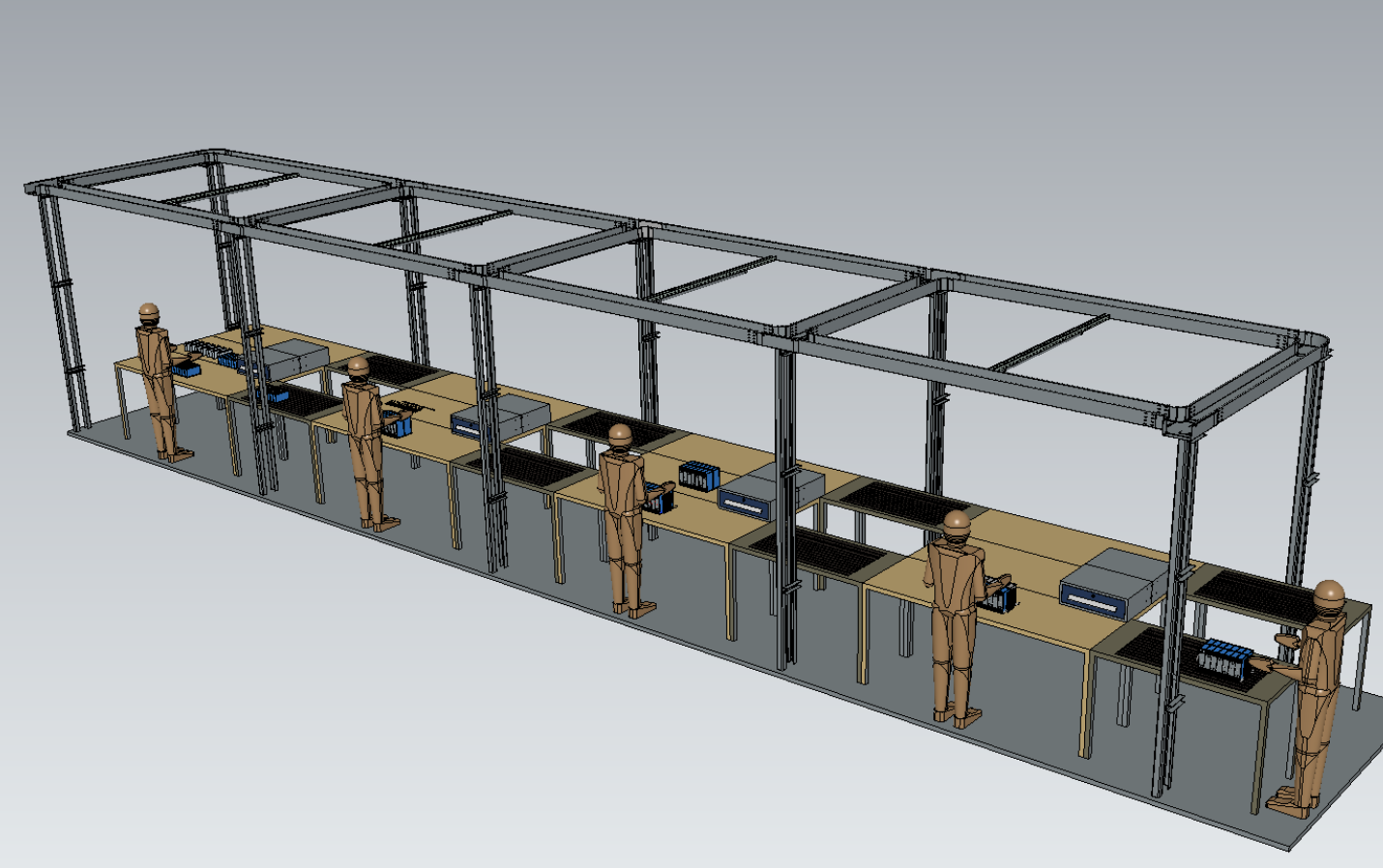

The prototype production line is set up as a cooperation project between Fraunhofer HHI and VoltaMove in Q2/2023. This line produces reproducible, quality-controlled LVDC battery systems with quantities up to 100 battery modules per week. The production takes place manually in the first step and is then partially automated in the course of the year.

Fraunhofer HHI

We are proud to have the Fraunhofer HHI as our R&D partner.

VoltaMove is based on know-how and patents of the Fraunhofer HHI and initially builds up a partially automated prototype production line for the production of LVDC battery modules in the premises of the HHI at the Goslar location.

The Fraunhofer HHI at the Goslar site – together with the Forschungszentrum Energiespeichertechnologien (EST) of the Technical University of Clausthal – has been operating for several years a battery test centre to carry out electrical and/or thermally induced abuse from cell to system level. These tests are carried out as direct order research (e.g. automotive industry) or in cooperation with the VDE, certifications/approvals are prepared or carried out.

Batteries are classified as dangerous goods.

The storage of cells or battery modules is already carried out at the Goslar location correspondingly prepared rooms. These are to be expanded in 2023 by suitable fire protection measures: sensor-controlled sprinkler systems and and special extinguishing media for lithium batteries. The combination of both components has already been successfully tested with the companies involved in the battery centre of the Fraunhofer HHI.

Battery transport containers and transport companies are available (truck or train). In the past, the Fraunhofer HHI. HAS successfully tested transport containers for Litihion battery systems in various sizes, or accompanied corresponding approvals for this.